Anti-fringing Technology for IR-Detectors

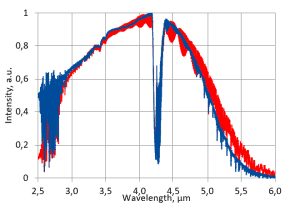

Laser absorption spectroscopy and optical spectroscopic techniques is of great use in a variety of gas detection applications, as it offers high speed and high precision capabilities for detecting and monitoring numerous gas species.

Our supplier VIGO Systems uses GaAs substrate as the basic material for its IR-detectors. However, due to the high refractive index (n=3,3) using GaAs generates numerous problems, among other the formation of the etalon effect.

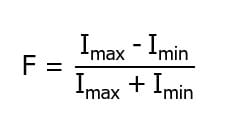

The Optical Fringing equation

The presence of the etalon effect, also known as optical fringing effect, influence signal fluctuations (noise) which is a limiting factor for laser absorption spectroscopy. Optical fringing is determined as the local signal amplitude to its mean value ratio and is a result of the interference of radiation reflected on the optical elements.

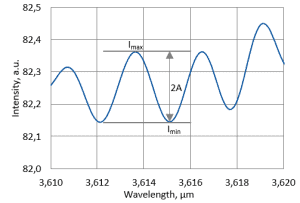

The Optical Fringing effect

The interference fringes stem from the optical system (Fabry-Pérot etalons between reflecting or scattering surfaces such as mirrors, lenses, optical fiber end faces, components of multipass cells, detector and laser package windows and semiconductor structure surfaces).

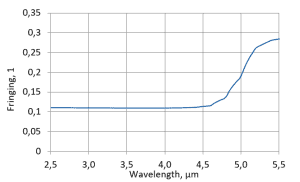

Fringing vs. wavelength

For radiation wavelengths above λpeak fringing increases significantly due to the weaker absorption of long wavelengths in the absorber. This means that more radiation is reflected from the metallization of the detector structure which contributes to greater fringing as shown in the graph below.

Solving fringing issues

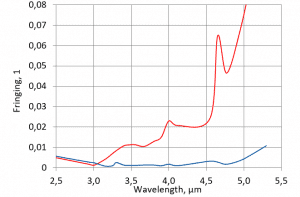

To account for fringing VIGO System has developed their own anti-fringing technology. Based on an internal modification of the detector structure the technology enables results where the fringing is 10 – 40 times smaller compared to standard IR detectors. After the growth the wafer is characterized and specially processed to manufacture detection structures immune to generating of optical fringes.

Application specific needs

This detection structure can be fitted with anti-reflection coated (available upon request) which slightly improves fringes reduction, which may be of importance in applications that require very high accuracy i.e. trace gas detection.

Further modifications can be applied based on customers needs.

PRODUCTS WITH ANTI-FRINGING TECHNOLOGY

Learn more about Anti-Fringing Technology and IR-Detectors?

We are here to help!

We are here to help!