MOTION SYSTEMS FOR TACTILE AND OPTICAL TESTING OF ELECTRONIC DEVICES

For tactile and optical testing of electronic devices you need a motion system able to inspect from various angles with high repeatability and force control. We can together with our Suppliers help design and build a flexible motion systems for various test methods that can be integrated into your production line while maintaining capacity and throughput.

Electronic devices are smaller and more complex than ever, while operating in environments and an with components that require tactile, optical, and electronic testing methods. The Motion System for these devices in final assembly demands precise positioning of the inspection tool in several degrees of freedom.

Motion System Highlights

- A broad range of motion technologies to adapt to the most advanced design solutions

- Achive coordinated motion of all axes for maximum throughput with an industrial high-performance motion control platform

- Flexible EtherCAT® connectivity provides easy connection and management of third-party sensors and test devices

- Possibility to integrate as a subsystem under most PLCs and automation controllers

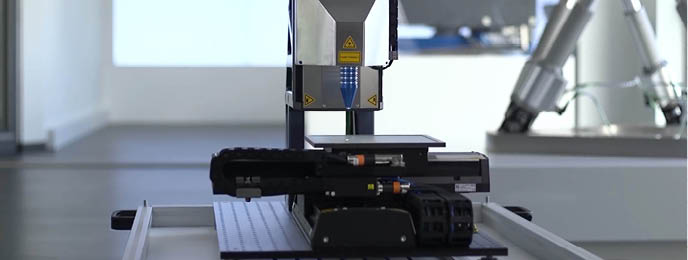

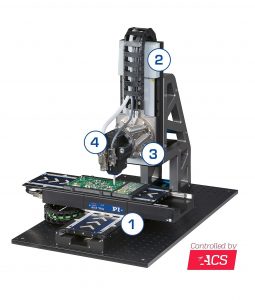

1. Workpiece Positioning

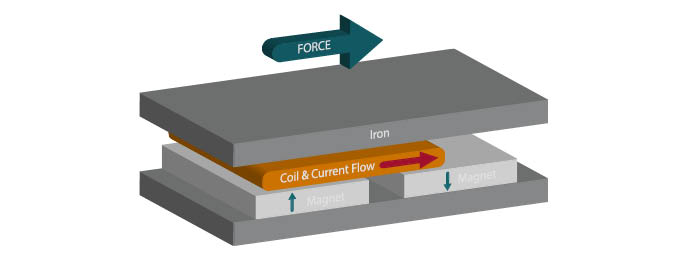

- Achieve high precision and high velocity with magnetic direct drive linear motor

- 1nm resolution with absolute encoder

- Drag chain cable management for XY configurations

- Product example: V-551 Precision Linear Motor Stage

2. Positioning of Testing Device

- Option of voice coil- or ball screw linear motor

- Integration of Cable

- Linear encoder for direct measuring

- Product example: M-511 High-Precision Linear Stage

3. Sensor Positioning at Various Angles

- Six degrees of freedom

- Parallel-kinematic hexapod

- Freely definable center of rotation

- Product example: H-811 6-Axis Miniature Hexapod

4. Force Control of Measuring Sensor

- PIMag® voice coil linear actuator

- 1 mN resolution with force sensor

- Compensate Weight force

- Product example: V-275 PIMag® Voice Coil Linear Actuator

Motion Controller

The motion control platform can operate as a subsystem or independent under most PLCs and automation controllers using ACS EtherCAT-based solutions.

|

|

Learn more about our Solutions?

We are here to help!

We are here to help!

Related Pages

* This page is a rendition from our Supplier, Physik Insturmente GmbH, Tactile and Optical Testing of Electronic Devices page.